Mastering Ammonia Preparation: Essential Techniques for Safe and Effective Synthesis

Ammonia, or NH₃, powers much of our world. Farmers use it to make fertilizers that feed billions. Factories turn it into nitric acid for explosives and plastics. In medicine, it helps create drugs that save lives. But getting ammonia right matters a lot. One slip in preparation can lead to waste or danger. Think of it like baking a cake: wrong ingredients ruin the batch. Safe and smart methods keep things running smooth. Let's dive into how you can master ammonia preparation.

Introduction: The Crucial Role of Ammonia in Modern Industry

Ammonia stands as a key player in today's industries. It boosts crop yields through fertilizers like urea. In manufacturing, it sparks reactions for chemicals we use daily. Pharma labs rely on it for vital compounds. Yet, precise preparation is key. Poor methods cut efficiency and risk harm. Quality control ensures pure output every time.

Section 1: Understanding the Chemistry of Ammonia Synthesis

Ammonia synthesis starts with basic chemistry. You combine nitrogen and hydrogen under right conditions. This process shapes how we produce tons of ammonia yearly. Labs and plants both use these ideas. Knowing the basics helps you avoid common pitfalls.

The Haber-Bosch Process: Foundation of Industrial Production

The Haber-Bosch process changed the game in 1910. Fritz Haber and Carl Bosch figured out how to make ammonia from air's nitrogen and hydrogen from water. The reaction is N₂ + 3H₂ ⇌ 2NH₃. It's reversible, so yields stay low without tweaks.

Le Chatelier's principle guides the fixes. High pressure shifts the balance toward ammonia. Around 200 atmospheres push more product. Heat at 400-500°C speeds it up but limits yield. Cool it down after to grab the gas.

This method feeds half the world's population via fertilizers. Plants run non-stop, churning out millions of tons. You can scale it for big ops or tweak for labs.

Catalytic Systems and Their Evolution

Catalysts make the magic happen. Iron works best, mixed with potassium oxide for promotion. Calcium and aluminum oxides boost it too. These cut the energy needed for bonds to break.

Temperatures hit 450°C, pressures reach 300 atm. That's harsh, but catalysts handle it. Early ones wore out fast. Now, ruthenium-based options run at lower pressures, like 100 atm. This saves costs in new plants.

Take BASF's upgrades. They extended catalyst life from months to years. Impurities still challenge, but designs fight back. For your setup, pick catalysts matched to scale.

Feedstock Purity Requirements

Clean inputs matter most in ammonia preparation. Nitrogen comes from air, but oxygen slips in. Hydrogen from syngas carries carbon monoxide. Sulfur poisons the catalyst quick.

Remove these with scrubbers and filters. Desulfurization uses zinc oxide beds. CO converts via shift reactions. Pure feeds extend catalyst runs by years.

Dirty stocks cut output 20-30%. One plant downtime from poison costs millions. Test feeds often to stay safe.

Section 2: Laboratory-Scale Ammonia Preparation Methods

Labs offer hands-on ways to make ammonia. These suit teaching or small tests. Safety comes first with gases and heat. Pick methods that fit your gear.

Direct Synthesis from Nitrogen and Hydrogen (Small Scale)

Small-scale direct synthesis mimics industry. Set up a high-pressure reactor, like a steel bomb. Feed nitrogen and hydrogen in 1:3 ratio. Heat to 500°C with iron catalyst.

Pressure builds to 100 atm. Watch gauges close. Yield tops at 10-15% per pass. Recycle unreacted gases for better results.

Safety rules: Use blast shields. Vent pressure slow. One leak can fill a room fast. This method teaches the Haber-Bosch heart.

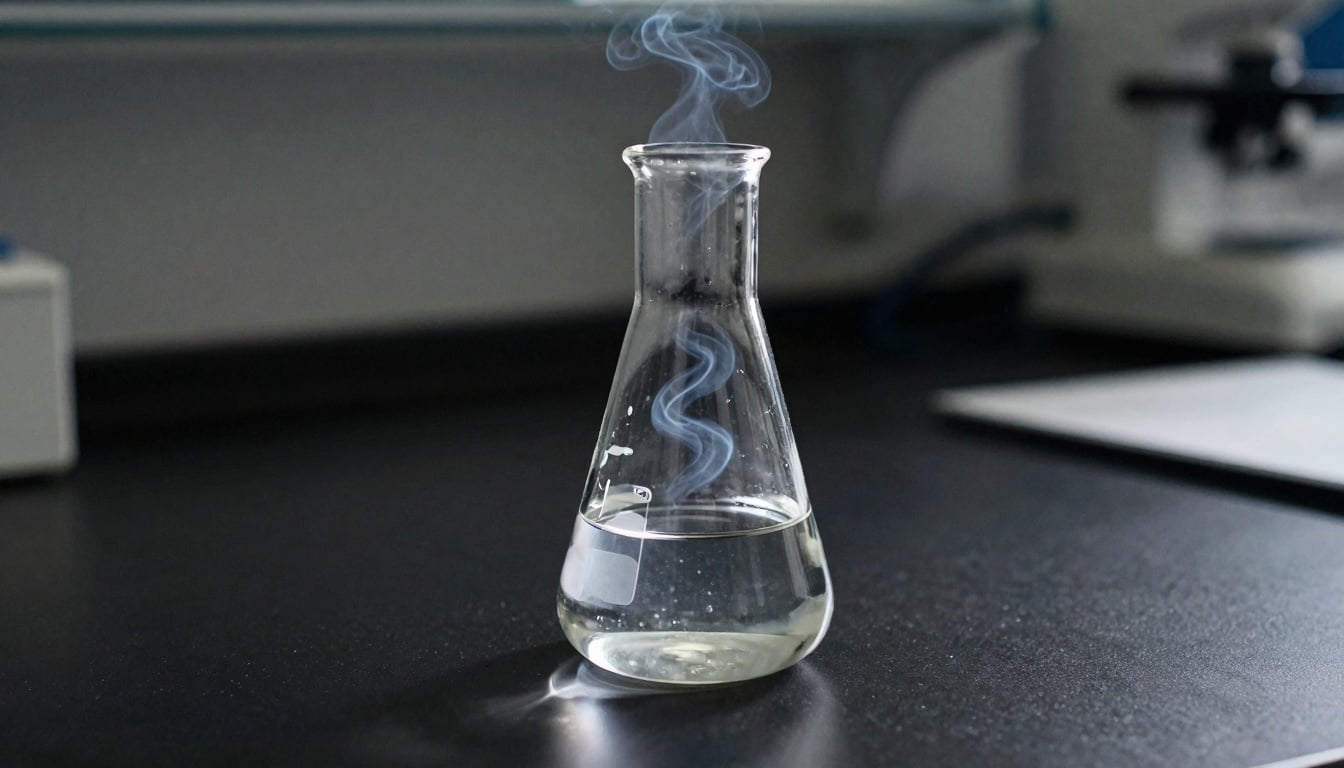

Preparation via Ammonium Salt Decomposition

Decompose salts for easy lab ammonia. Mix ammonium chloride with sodium hydroxide. Heat in a flask: NH₄Cl + NaOH → NH₃ + NaCl + H₂O. Gas bubbles out white.

Collect by downward air displacement. Ammonia's lighter than air, so it flows up. Use a trough setup.

For 100 ml gas, take 0.5 g NH₄Cl and 0.4 g NaOH. Heat gentle at 200°C. Test purity with litmus—it turns blue. This beats pressure risks.

- Ratio tip: Always 1:1 molar for full reaction.

- Heat slow to avoid splatter.

- Dry the gas over lime if needed.

Sulfate salts work too, like (NH₄)₂SO₄. Just adjust base amount.

Generating Ammonia from Urea

Urea breaks down to ammonia neat. Heat CO(NH₂)₂ at 150-200°C. It hydrolyzes: CO(NH₂)₂ + H₂O → 2NH₃ + CO₂. No catalyst often, but acid speeds it.

Pressure helps in sealed tubes. Byproducts include CO₂, so separate with absorbers. Labs use this for quick demos.

Watch for pressure buildup from gases. Cool before opening. Yields hit 90% with control. Great for educational ammonia preparation.

Section 3: Critical Safety Protocols in Ammonia Handling

Ammonia bites back if mishandled. It's corrosive and smells strong. Prep spots need plans. Follow rules to stay safe.

Hazard Identification and Exposure Limits

Ammonia burns skin and eyes on contact. Inhale it, and lungs suffer. Short exposure irritates; long harms deep.

OSHA sets PEL at 50 ppm over 8 hours. TLV sits at 25 ppm. IDLH is 300 ppm—escape fast there. Stats show 100 U.S. incidents yearly from leaks.

Know signs: watery eyes, cough. Test air regular. This guards workers in ammonia synthesis.

Personal Protective Equipment (PPE) Requirements

Gear up right for handling. Respirators with ammonia cartridges block vapors. Chemical goggles shield eyes. Butyl rubber gloves resist penetration.

Full suits for big spills. Boots and aprons add layers. Train on fit—loose masks fail.

PPE saves lives. One study cut injuries 70% with proper use. Check gear daily.

Emergency Response and Leak Mitigation

Spill happens—act quick. For skin, rinse 15 minutes with water. Inhale? Move to fresh air, give oxygen if needed.

Leaks? Ventilate wide. Use water spray to drop vapors. Absorb liquid with sand, not rags.

Call pros for big ones. Drills keep teams sharp. This turns bad days better.

Section 4: Purification and Storage of Prepared Ammonia

Pure ammonia lasts longer. Clean it post-synthesis. Store smart to avoid loss. These steps finish your prep.

Techniques for Ammonia Gas Purification

Dry gas first. Calcium chloride soaks water vapor. Molecular sieves trap more. Pass through cold traps at -50°C.

Remove impurities with scrubbers. Sulfuric acid catches ammonia traces—no, wait, for purification, use selective absorbers for leftovers like H₂.

Test purity via spectroscopy. Clean gas boosts reactions downstream.

Liquefaction and Anhydrous Storage

Turn gas to liquid easy. Cool below -33.3°C or press at room temp to 8 atm. It condenses clear.

Store in DOT-approved cylinders, steel with valves. Keep under 45 psig. Secure against falls—impacts burst them.

Handle with carts, not hands. Label clear: "Ammonia, Anhydrous." This prevents mishaps in storage.

- Tip: Check valves weekly for leaks.

- Store cool, away from acids.

- Inspect tanks yearly.

Preparation of Aqueous Ammonia Solutions (Ammonium Hydroxide)

Bubble gas into water slow. Use deionized to avoid ions. Aim for 28% solution—exothermic, so cool the bath.

Stir constant for even mix. Measure pH to hit 11-12. Label with concentration.

This makes cleaners or buffers. Dilute further for labs. Heat control stops splashes.

Conclusion: Precision and Vigilance in Ammonia Management

Ammonia preparation blends science and care. From Haber-Bosch giants to lab tricks like salt breakdown, methods vary. Key is control: pure feeds, right catalysts, smart pressures.

Safety nets it all. PPE, limits, quick responses keep risks low. Purification seals the deal for quality use.

Master these, and you handle ammonia like a pro. Start small in lab, scale with knowledge. Grab gear, follow steps—your next project succeeds. Check local regs before diving in.

No comments:

Post a Comment